shopping_basket

Enhanced Oil Recovery chips

tune

Filters

To study thermal, chemical and microbial Enhanced Oil Recovery (EOR) and the effectiveness of these technologies, the most accurate way is to use a physical rock. The use of ‘real’ rocks has several major drawbacks, however. Therefore, Micronit has developed three types of Enhanced Oil Recovery chips in collaboration with several leading industrial partners. This way, experiments can be conducted on surrogate rocks, using lab-on-a-chip technology. These chips can be used for several types of research concerning Enhanced Oil Recovery, whether it is for reservoir engineering or environmental issues. Three different types of EOR chips have been developed, each designed to mimic a different rock structure. The chips are available with either a random, a uniform or a physical rock structure network.

Jumpstart your projects with our accesible webstore products

Enhanced oil recovery (EOR) chips can be used to verify calculation models, providing an optical clear surrogate rock. Known geometrical conditions and optical clear chips create optimal conditions to study physical processes that normally occur inside rock formations. For more information, visit our dedicated page on EOR chips.

We offer these chips in three designs: Physical Rock, Random, and Uniform Network.

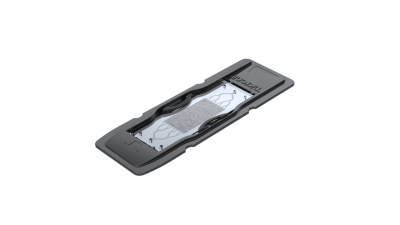

Microfluidic EOR Chips

Enhanced Oil Recovery (EOR) chips are advanced microfluidic devices designed to optimize and simulate the processes involved in the extraction of oil from reservoirs. These chips feature intricate channel structures that enable precise control and manipulation of fluid flows under reservoir conditions. EOR chips are pivotal in applications such as assessing the effectiveness of chemical and thermal recovery methods, optimizing injection strategies, and visualizing fluid interactions within porous media. Their ability to replicate complex subsurface environments makes them invaluable for improving oil recovery techniques and enhancing the efficiency of extraction processes in the petroleum industry.

Enhanced Oil Recovery (EOR) Chips Developed and Manufactured by Micronit

Micronit is a trusted partner for the development and manufacturing of microfluidic components and consumables, including Enhanced Oil Recovery (EOR) chips. We welcome collaboration with partners aiming to create customized products tailored to their specific requirements. Our portfolio includes projects at various stages of maturity, from initial development to full-scale manufacturing. Our diverse customer base, from innovative start-ups to leading global players in the oil and gas industry, depends on our extensive experience and proven track record in delivering high-quality EOR chips and other microfluidic solutions. We also support top-tier academic institutions by providing tools essential for cutting-edge research.

Optimal management of small fluid volumes

Enhanced Oil Recovery (EOR) chips play a crucial role in the oil and gas industry due to their ability to precisely manage small fluid volumes. This precision is essential for applications such as optimizing fluid injection processes, enabling efficient and effective recovery of hydrocarbons. In the development of EOR techniques, these chips facilitate the rapid testing and implementation of various recovery methods by ensuring uniform distribution of injected fluids, making them ideal for improving extraction efficiency and reducing operational costs.

Available types of EOR chips

At Micronit, we have designed chips that mimic physical rock structures as accurately as possible. Our chips are even optically clear, allowing you to see through the on-chip fabricated rock. These chips enable your EOR experiments to be carried out in a simple and controlled manner.

Whether using thermal (TEOR), chemical (CEOR), or microbial (MEOR) methods, our lab-on-a-chip technology facilitates reliable testing of the effectiveness of any enhanced oil recovery method. These chips are ideal for initial experiments and proof of concept.

Micronit’s EOR chips are available in three varieties, differentiated by the fluidic network on the chip surface that mimics the rock structure. You can choose between a random structure, a uniform structure, and a physical rock structure.

The growing demand of EOR Chips

As conventional extraction methods reach their limits, EOR technologies are becoming essential for maintaining production levels. The growing need for EOR chips is driven by the dual pressures of economic efficiency and environmental responsibility. By investing in EOR chips, companies can tackle the pressing issues of declining well productivity and high operational costs while also aligning with global sustainability goals. Micronit's state-of-the-art chips, designed for thermal, chemical, and microbial EOR methods, enable efficient, controlled recovery processes.