shopping_basket

Enhanced oil recovery (EOR) setup - low pressure (no pumps included)

This setup contains a chip holder, chips for enhanced oil recovery (EOR) and tubing. In addition you can select the EOR-chip of your choice: with a uniform, random or physical rock structure and an optional hydrophobic coating.

These microfluidic chips can be used in enhanced oil recovery research, reservoir engineering or environmental research. They are used to verify simulation models of rock-pore structures in the EOR field.

This setup is the best choice when you use a pressure up to 4-5 bar. In case more pressure is desired our is the best choice.

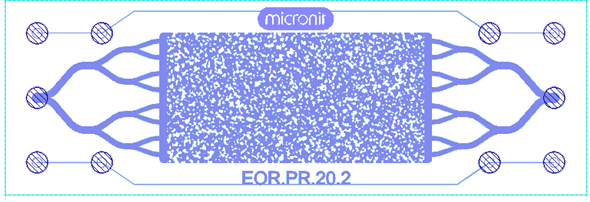

Physical rock network

This chip is designed by randomly placing rock shaped structures on the chip to resemble the shape that is obtained by cutting rock as accurately as possible. This random structure results in throats and channels between the rock structures. This method of random placement does not give information on throat size distribution. For simulation purposes, the mask (2D) design is available on request. However, experience has taught us that the complexity of this structure makes it challenging to run computer simulations on.

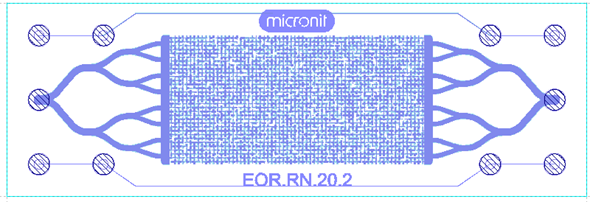

Random network

Random network porous structure chip, often used for Chemical Enhanced Oil Recovery (CEOR) and Microbial Enhanced Oil Recovery (MEOR) experiments.

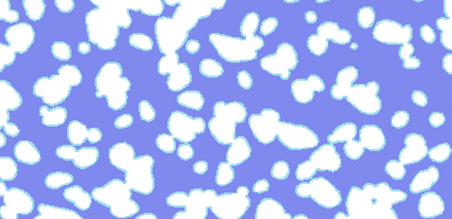

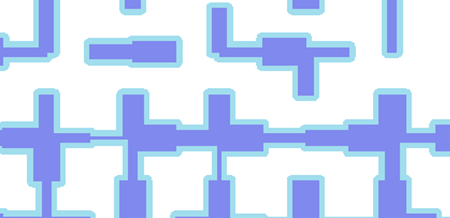

Uniform network

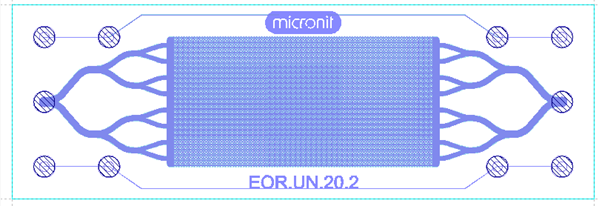

A systematically organized and well-defined rock-pore structure of equally sized pores and channels.

| Unit of measurement | Bundle |

|---|---|

| Application | Enhanced Oil Recovery |

| Holder concept | Fluidic Connect Pro |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| EOR.UN.20.2 - Drawing | Drawing for the EOR porous medium chip with Uniform Pore Network. Items 02978 and 02198 | 378.2 KB | Download | |

| EOR.RN.20.2 - Drawing | Drawing for the EOR porous medium chip with Random Pore Network. Items 02977 and 02199 | 123.7 KB | Download |

Customer Questions

We found other products you might like!

- EOR starter kit low pressure - topconnect (incl. syringe pumps)

As low as $4,160.72