shopping_basket

product spotlight

Micromixers

Microfluidic mixing is revolutionizing the way small fluid volumes are handled, making it a vital process in biomedical research, diagnostics, and drug development. At Micronit, we excel in providing high-quality microfluidic mixer chips that ensure precise and efficient fluid mixing, essential for lab-on-a-chip platforms.

Whether you need a stand-alone mixer chip or an integrated solution within a larger microfluidic device, Micronit offers a range of micromixer options to meet your needs. Our mixer chips are designed to optimize fluid handling, overcoming the limitations of laminar flow and enhancing mixing efficiency through innovative techniques.

Micromixers developed and manufactured by Micronit

Micronit is an experienced development and manufacturing partner for microfluidic components and consumables. We are open to partners that wish to develop a new product, tailored to their specific wishes and needs. We run multiple projects at different maturity stages from development to manufacturing. Our customers, varying from ambitious start-ups to one of the key global players in the next gen sequencing market, rely on our track record of years of supplying our optical grade, high-quality flow cells and other microfluidic products. We also support leading academics in providing the tools for groundbreaking research.

Why Micromixers are essential for Biomedical Research?

Microfluidic micromixers are essential in numerous fields due to their ability to precisely handle small fluid volumes. This precision is vital for applications such as Cell Analysis, enabling high-throughput screening. In drug development, micromixers facilitate the rapid synthesis and testing of pharmaceuticals by ensuring uniform mixing of lipid solutions (LNP's), making it ideal for developing advanced medicines

Understanding Laminar Flow in Microfluidic Systems

In microfluidic systems, the flow of fluids typically occurs under laminar conditions due to low Reynolds numbers. This means that two streams of miscible liquids will flow side by side without significant mixing, relying solely on diffusion, which can be a slow process. To address this, microreactors use microfluidic channels to facilitate more effective mixing.

Various techniques are employed to accelerate mixing under laminar flow conditions. These methods involve creating internal "folds" within the fluid channels, which shorten the diffusion path and promote rapid homogenization of the fluids.

Choose Your Micromixer Type

Micronit offers a diverse catalog of micromixer chips, each designed for specific mixing requirements. Our standard mixer chips are crafted from Borosilicate glass using wet etching or laser ablation techniques. Here are the available types:

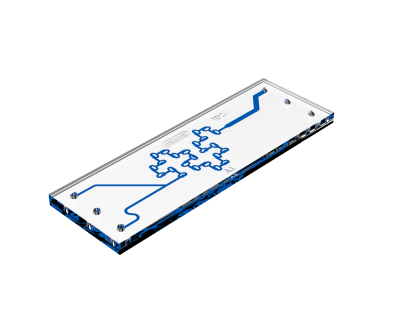

Teardrop Micromixer

- Ideal for: Fast and efficient mixing of liquids with low Reynolds numbers (RE < 100).

- Mechanism: Splitting and recombination of the liquid stream through teardrop-shaped elements.

Swirl Micromixer

- Ideal for: Liquids with higher Reynolds numbers (RE > 50).

- Mechanism: Fast downward spiral flow in "swirl chambers" that initiate mixing

Zigzag Micromixer

- Ideal for: Creating chaotic advection in laminar flow regimes.

- Mechanism: Sharp corners create imbalances in the flow, enhancing mixing and reducing mixing time.

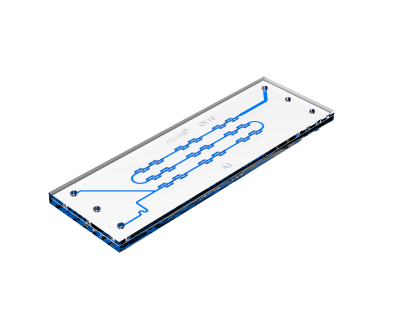

Folding Micromixer

- Ideal for: Effective mixing along the length of the mixing channel.

- Mechanism: Split-and-recombine flow channels with multiple splits create parallel diffusion planes.

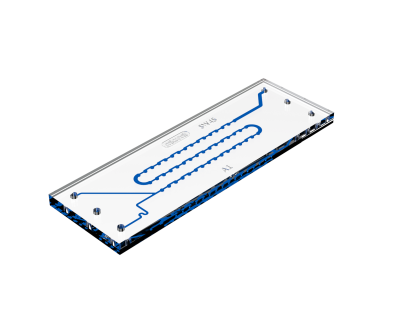

Serpentine Micromixer

- Ideal for: Stable laminar flow with extended mixing periods.

- Mechanism: Diffusion-based mixing through a serpentine channel, allowing for precise monitoring.

Micronit Assists in the Flow Cells you need

in 3 simple steps

1. Submit your idea

Share your idea or design with us to initiate the prototyping process. We're eager to understand your project's unique requirements.

2. Technical readiness

After receiving your submission and reviewing your design, we'll discuss your specific needs in detail, ensuring alignment with both your objectives and our expertise.

3. Production

Finally, we transition to the technical development and production, transforming your concept into a prototype.

Submit your idea