shopping_basket

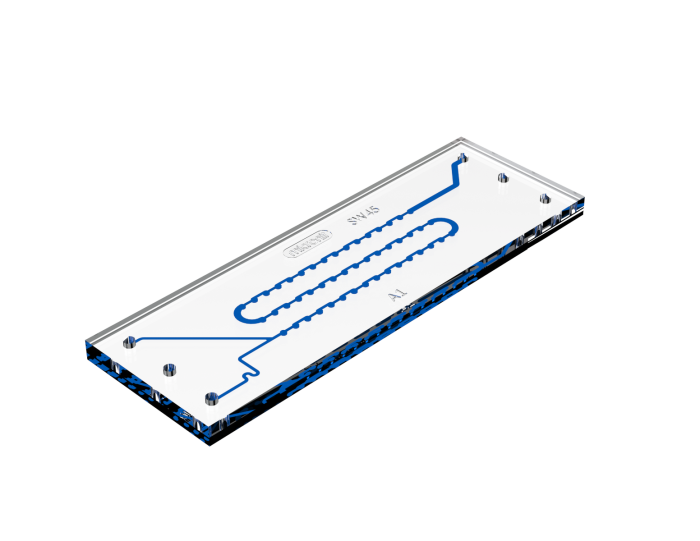

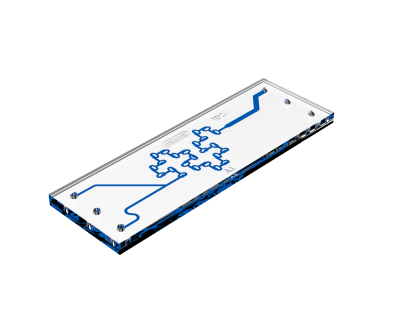

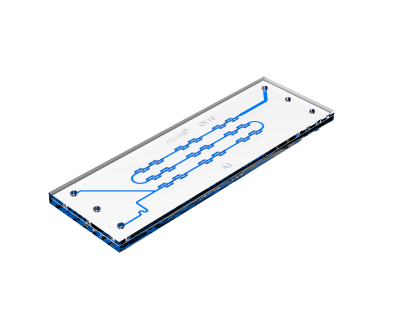

Swirl mixer - fully transparent

SKU

11008013

Availability:

check_circle In stock

$468.23

per pack of 2

Pack of 2 swirl micro-mixers

Why use a micro fluidic mixer?

Microfluidic chips often operate laminar flow regime which are not ideal circumstances for mixing of liquids. Also, not all combinations from liquids mix as easily. This can result in the need for long mixing lengths or ineffective mixing. Mixing is sometimes also applied to create nanoparticles; such processes use chemical interaction between liquids that result in particle generation at liquid contact surfaces. Micro mixers increase such liquid interaction and offer a relatively stable mixing condition which results in more controlled liquid interaction.

What are the advantages?

By adding mixing structures to a microfluidic setup or design the chip’s footprint can be reduced compared to incorporating just a long channel. Also, achievable mixings can be improved, which is often beneficial for results in subsequent analysis steps.

Nanoparticles with a much more contestant size distribution are created due to the highly controlled and predictable liquid interaction.

Swirl micromixers

- Ideal for: Liquids with higher Reynolds numbers (RE > 50).

- Mechanism: Fast downward spiral flow in "swirl chambers" that initiate mixing

- Fully transperent: The mixers are wet etched for optimal sight from both the top as bottom surface.Our etching process create ultra smooth surfaces.

Alternative mixer types

An overview page with alternative geometries can be found .

Interfacing

The recommended interfacing tool is our . In addition you will need a . The chips are also compatible with the .

| Unit of measurement | pack of 2 |

|---|---|

| Holder concept | Fluidic Connect Pro |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Swirl mixer SW45 - fully transparent - Drawing | Drawing 42010324 Swirl Mixer SW45, 11008013 | 110.2 KB | Download |

Customer Questions

We found other products you might like!

- Product bundle with interfacing and microfluidic chips

From $2,252.24

To $24,165.35

- Mixer en Reactor starter kit - topconnect (incl. syringe pumps)

As low as $4,160.72