shopping_basket

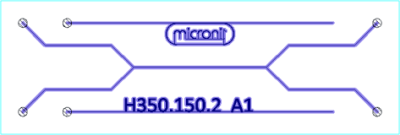

Thin bottom flow cell - topconnect

SKU

Flow_cell_conf

Availability:

check_circle In stock

As low as $348.62

per pack of 3

Pack of 3 thin bottom flow cell chips.

Application possibilities

A flow cell / observation cell is a sample cell designed so that liquids sample, for instance containing cell’s, proteins or particles, can be continuously flowed though a observation area.

Our glass flow’s cell are intended for situation where the optical properties are extremely critical and are suitable for high resolution imaging. They are often used in combination with fluorescent markers.

As alternative to continuously flowed sample it’s also possible to apply stopped flow observation by adding pressure control on both the cell inlet and outlet.

Research examples can be for instance:

- In-line sampling of liquids, mostly using a optical read out.

- Cell observation / counting

- Measurement of fluorescent response.

- Combined with surface chemistry they are used as base for NGS technology (Next-Generation Sequencing)

Unique selling point

- The channels doesn’t have any substantial roughness and are fully optical transparent due to the etching process used.

- Glass offers sublime optical transparency and low autofluorescence.

- When fluorescent markers are used we have also a D263-Bio version available for even lower autofluorescence in some critical wave length areas.

- Compatible with a #1 (11003196, 11003164) or #1.5 (11003133) coverslip

- Available in different channel dimensions.

- Available with hydrophobic coating.

Key features of the products

| Item | Coating | Channel width | Number of channels | Channel height | Thin bottom thickness | Material |

|

11003133

|

No coating, hyrophilic surface | 500µm, 1500µm, 1000µm | 3 | 50µm | 175µm | D263 Bio |

|

11006327

|

Hyrophobic coated | 500µm, 1500µm, 1000µm | 3 | 50µm | 175µm | D263 Bio |

| 11003196 | No coating, hyrophilic surface | 500µm | 3 (same channel size) |

50µm | 145µm | D263 Eco |

| 11006345 | Hyrophobic coated | 500µm | 3 (same channel size) |

50µm | 145µm | D263 Eco |

| 11003164 | No coating, hyrophilic surface | 1500µm | 3 (same channel size) |

50µm | 145µm | D263 Eco |

| 11006338 | Hyrophobic coated | 1500µm | 3 (same channel size) |

50µm | 145µm | D263 Eco |

D263 Bio offers a reduced autofluorescence when used in combination with fluorescent markers with emissions above 600nm.

Interfacing

This product is compatible with our .

Because of the limited chip thickness it’s necessary to use the metal strips included with the holder, see here for more information.

To connect all three channels at the same time, you need six ferrules. The ferrules are available in sets of five. Make sure you order two sets if you want to connect three channels at the same time.

| Unit of measurement | pack of 3 |

|---|---|

| Interface type | Topconnect |

| Channel location | Channels are located 1050µm from the top surface. The distance form the bottom surface is 145µm (version with 3 different channels) and 175µm for the version with the same channels. |

| Chip thickness | 1.8mm |

| Chip material | Borosilicate glass |

| Number of inlets | 3 |

| Number of outlets | 3 |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| 11003164 / 11006338 Drawing Flow cell chip 1.5mm width | Drawing for Flow cell chip 1.5mm width, items 11003164 (uncoated) / 11006338 (coated) | 260.1 KB | Download | |

| 11003196 / 11006345 Drawing Flow cell chip 0.5mm width | Drawing for Flow cell chip 0.5mm width, items 11003196 (uncoated) / 11006345 (coated) | 232.7 KB | Download | |

| 11003133 / 11006327 Drawing Flow cell chip variable width 175um bottom | Drawing for Flow cell chip variable width 175um bottom, items 11003133 (uncoated) / 11006327 (coated). | 206 KB | Download |

Customer Questions

We found other products you might like!

- Product bundle with interfacing and microfluidic chips

From $2,245.32

To $23,972.96

- Observation starter kit - topconnect (incl. syringe pumps)

As low as $4,147.93