shopping_basket

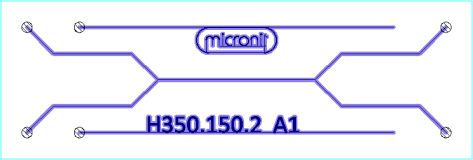

H-shaped channel for boundary flow experiment

SKU

config_H

Availability:

check_circle In stock

As low as $349.69

per pack of 3

H-shaped flow channel, ideal for boundary flow experiments. Available into two diferent channel sizes and optional thin bottom layer.

This H-shaped flow channel is an ideal solution for boundary flow experiments in which two liquids will flow in parallel and only diffusion will occur at the interface of both flows.

The channels are etched into borosolicate glass which creates extremly smooth channels which are fully transparend.

| SKU | Channel Width [µm] | Channel Height [µm] | Bottom layer thickness [µm] | Borosilicate glass |

| 11003577 | 350 | 150 | 700 | D263-Eco |

| 11003578 | 120 | 50 | 175 | D263-Bio |

| Unit of measurement | pack of 3 |

|---|---|

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| Number of inlets | 2 |

| Number of outlets | 2 |

| Channel width | 350µm or 120µm, depending on selection. |

| Coating | No coating (hydrophilic) |

Customer Questions