shopping_basket

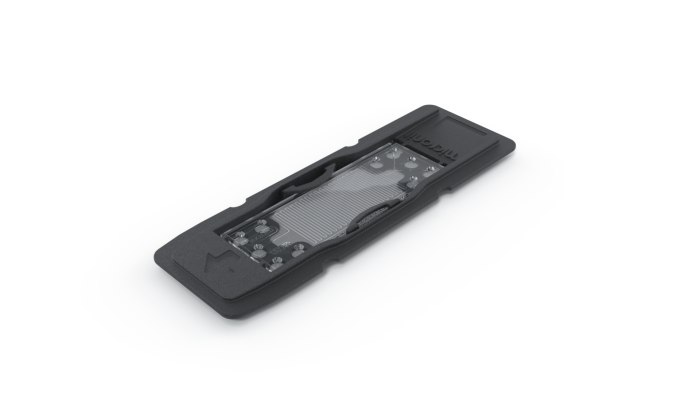

Serpentine channel / Microreactor, 140x250µm, 500mm length

SKU

11003033

Availability:

check_circle In stock

$416.59

per pack of 3

Flow cell with a serpentine channel with a length of 500mm. Channel width: 250µm, channel height: 140µm.

Application possibilities

This product is designed for observation purposes and offers sublime optical performance in combination with microscopy. This allows high resolution imaging.

Unique selling points

- For cell up to 110µm in diameter

- 500mm of observation length, 41 meanders of 11.62mm

- Low autofluorescence

- Manufactured from high-end glass, channels are extremely smooth and fully transparent.

- The channel contain 3 inlets, unused inlets can be blocked using .

Key features of the product are:

| SKU | Number of inlets | Number of outlets | Channel width | Flat channel area width | Channel height | Glass height on top of channel | Glass height below channel | Chip height |

| 11003033 | 3 | 1 | 250µm | 110µm | 140µm | 830µm | 830µm | 1800µm |

Interfacing

This product is compatible with our .

| Unit of measurement | pack of 3 |

|---|---|

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| Number of inlets | 3 |

| Number of outlets | 1 |

| Max. cell height | 110µm |

| Internal volume | Internal volume 15.2µl |

| Coating | No coating (hydrophilic) |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| Drawing 11003033 | Serpentine 140x250µm, 500mm | 99.7 KB | Download | |

| Drawing 11003040 | Serpentine 45x140µm, 350mm, TB | 76.9 KB | Download |

Customer Questions

We found other products you might like!

- Product bundle with interfacing and microfluidic chips

From $2,132.84

To $26,951.83

- Observation starter kit - topconnect (incl. syringe pumps)

As low as $4,073.05

- Mixer en Reactor starter kit - topconnect (incl. syringe pumps)

As low as $4,073.05