shopping_basket

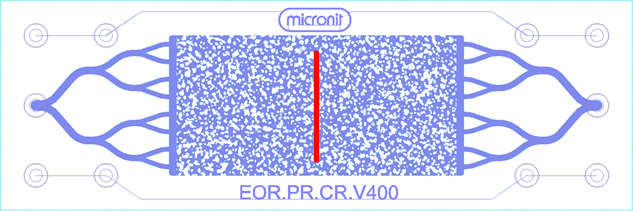

EOR - Physical Rock Structure with vertical crack - 400µm

SKU

11003201

Availability:

check_circle In stock

$799.53

per pack of 3

Enhanced Oil Recovery - Physical Rock Structure with a 400µm wide vertical crack.

This porous medium chip uses our Enhanced Oil Rcecovery Physical rock structure (sandstone) combined with a vertical crack added to the model.

The models help to provide insight how such a crack or void wil influence oil recovery.

The crack is marked in red in the picture below and is a void in the actual structure.

The crack is 400µm wide and has a length of 8mm.

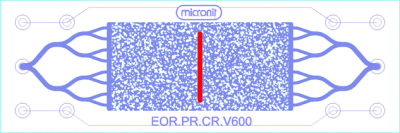

It's part of a series with also 150µm and 600µm wide cracks, which can purchased separately.

No coating is applied, the glas will have it's default hydrophilic behaviour.

This model is established together with Prof. Sebastiao Lucena from the Universidade Federal do Ceará.

| Unit of measurement | pack of 3 |

|---|---|

| Alternative item references | 03201, EOR.PR.CR.V400 |

| Application | Enhanced Oil Recovery |

| Interface type | Topconnect |

| Chip thickness | 1.8mm |

| Chip material | Borosilicate glass |

| Number of inlets | 1 |

| Number of outlets | 1 |

| EOR network type | Physical Rock |

| Coating | No coating (hydrophilic) |

| Crack Width | 400µm Wide Crack |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| EOR PR 20.2 Crack 400µm | Drawing for the EOR porous medium chip with a Physical Rock Network that contains a 400µm crack. Items 03201 and 03205. | 144.3 KB | Download |

Customer Questions

We found other products you might like!

- Enhanced oil recovery (EOR) setup - low pressure (no pumps included)

From $2,132.84

To $11,432.41

- Enhanced oil recovery (EOR) setup - high pressure (no pumps included)

From $2,457.76

To $11,341.90

- Product bundle with interfacing and microfluidic chips

From $2,132.84

To $26,951.83

- EOR starter kit low pressure - topconnect (incl. syringe pumps)

As low as $4,073.05