shopping_basket

Microfluidic EOR chips: Innovation in the oil and gas sector

- Microfluidic Expertise

- Reading time: 5 minutes

Microfluidic EOR chips: Innovation in the oil and gas sector

Did you know that fluid dynamics using microfluidic can revolutionize sustainable resource extraction and boost industrial innovation? EOR chips are revolutionizing how we approach oil recovery. The need for cleaner and more efficient energy extraction is greater than ever. Sustainability and efficiency are essential in the oil and gas industry.

Understanding microfluidics in EOR

EOR chips innovate the way we approach oil recovery. EOR chips, or Enhanced Oil Recovery chips, help the industry innovate by providing new methods and processes. These microfluidic devices are designed to imitate different soil structures, in order to study how the extraction process works. A visual window allows the observation of fluid interactions, which is not possible with real soil samples or on-site underground locations. Furthermore, by testing with exact copies of a design, the differences in oil extraction efficacy can be measured between different techniques and experiments.

Microfluidics is the science of controlling fluids at a sub-millimeter scale using channels etched into materials like glass or silicon. By manipulating fluids on a microscale, engineers can precisely analyze the properties of reservoir fluids, leading to better decision-making during exploration. Since the early 2000s, this technology has been applied to improve exploration and production processes (Mohammadi and Maghzi, 2019) [2]. Oil and gas professionals are realizing the potential of this technology, but the biggest challenges here are standardization and accessibility.

At Micronit, we aim to make a positive impact through our expertise in microfluidics. To push innovation forward, we developed an accessible setup with different types of EOR chips. More info here: Micronit EOR Chips.

Advantages of EOR chips

Recent studies demonstrate the numerous advantages of EOR chips:

- According to a study by Lifton (2019), microfluidic devices offer significant advantages in EOR research, including improved visualization and control over experimental parameters [1]. The primary advantage of EOR chips is their ability to replicate subsurface environments accurately. This feature allows for the effective assessment of chemical, thermal, and microbial recovery methods.

-

Recent research by Géraud et al. (2021) demonstrates how microfluidic devices can be used for fast screening of CO2 foam surfactants, highlighting the efficiency of these tools in EOR research [4]. The precise control over small fluid volumes helps optimize flow and distribution strategies, and visualize fluid interactions within porous media.

As a result, EOR chips are invaluable in enhancing oil recovery techniques, particularly as conventional extraction methods reach their limits.

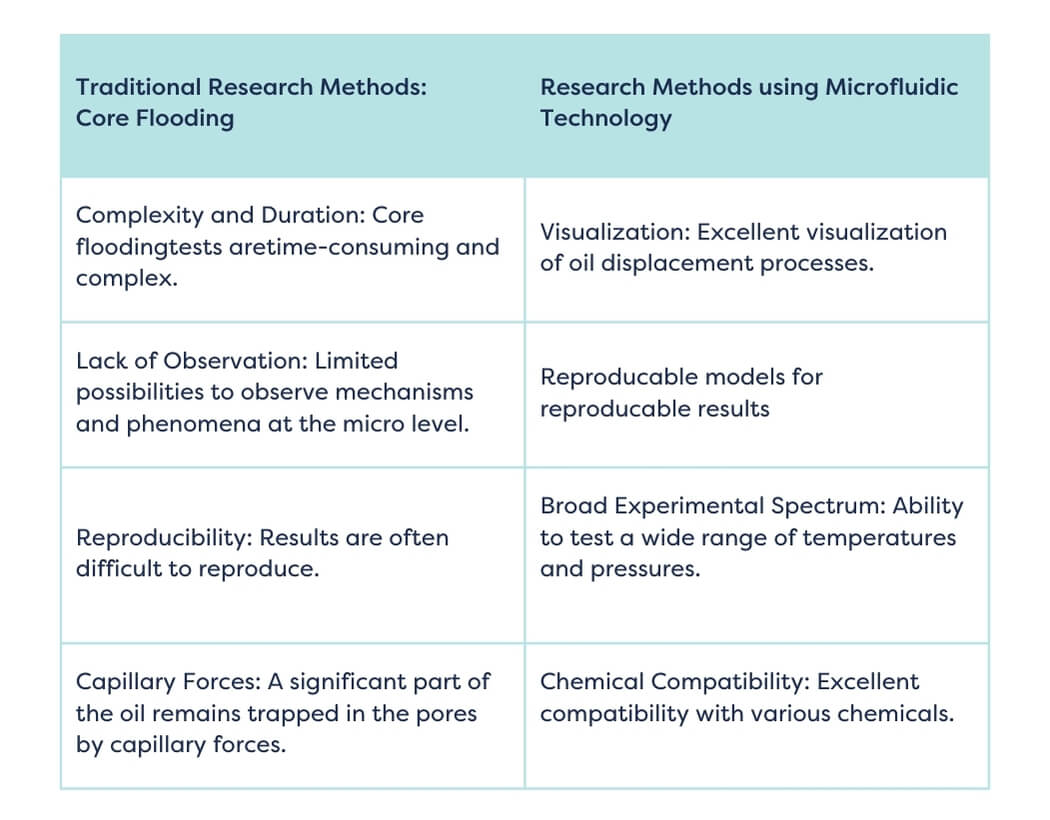

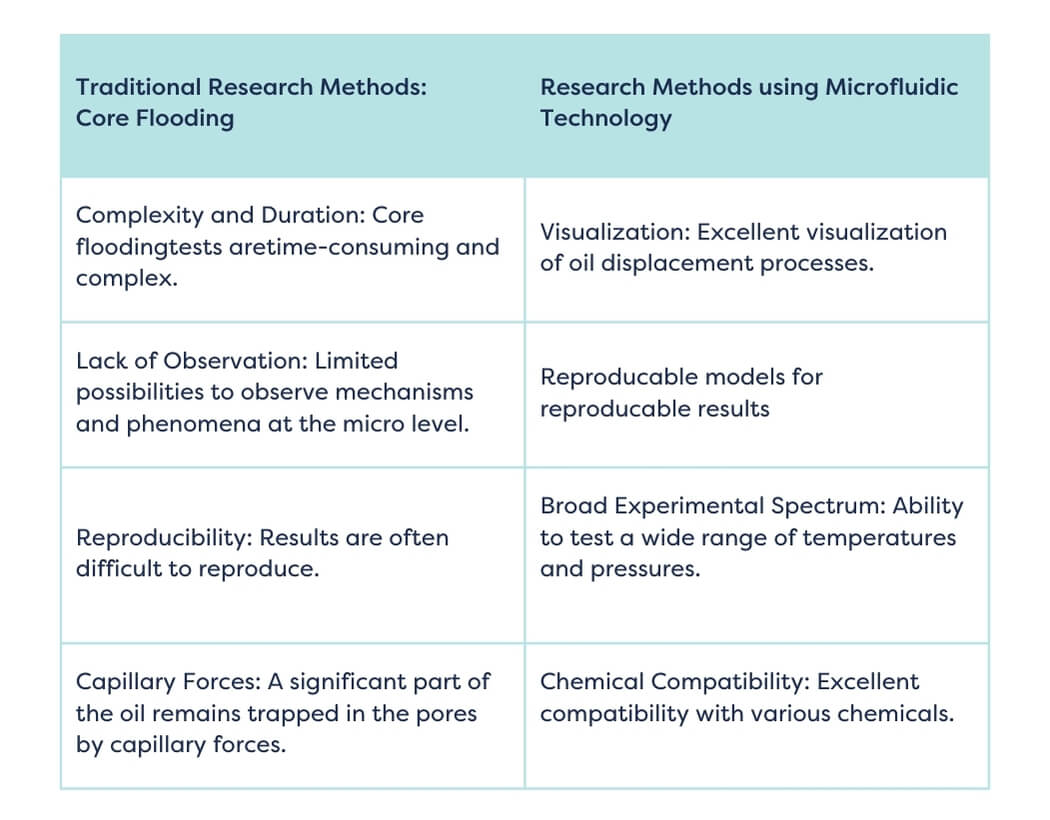

Traditional vs microfluidic research methods

Traditional EOR research involves core-flooding experiments, which inject fluids (like water, gas, or chemicals) into the core to observe how they displace oil and measure recovery efficiency. Key limitations include complexity, long testing times, limited visibility into micro-level mechanisms, and difficulties in reproducing results.

In microfluidic research, EOR microfluidic chips simulate oil displacement in porous media using microfluidic models. These chips offer precise control and visualization of fluid flows at the micrometer scale. Advantages include better visualization of oil displacement, reusability, and the ability to test a wide range of temperatures and pressures. This allows for the development and optimization of more efficient and insightful oil extraction methods.

Types of EOR chips

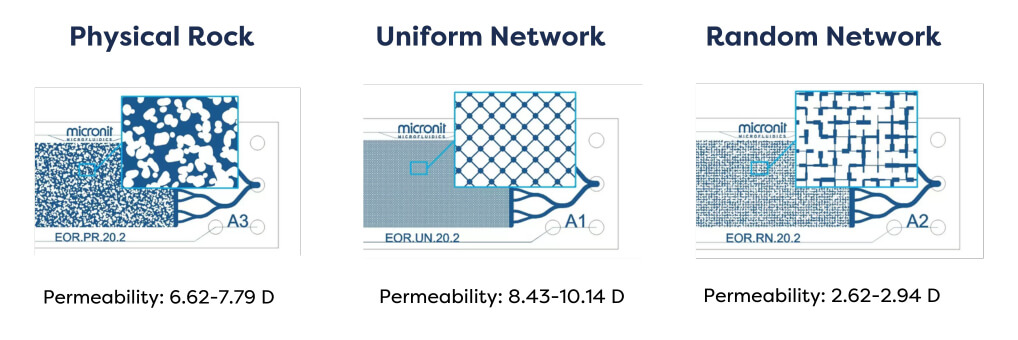

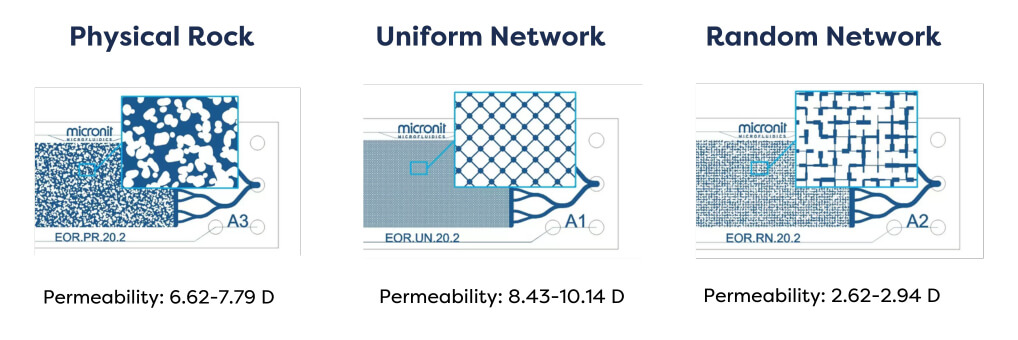

Micronit have developed a varieties of EOR chips, each tailored for specific applications:

- Random Structure: Features a randomly placed porous structure, ideal for Chemical (CEOR) and Microbial (MEOR) Enhanced Oil Recovery experiments. CEOR (Chemical Enhanced Oil Recovery) and MEOR (Microbial Enhanced Oil Recovery) are advanced techniques that use specially formulated substances or microorganisms to improve oil extraction efficiency.

- Uniform Structure: Offers a uniform porous structure, suitable for similar CEOR and MEOR applications. Often used for experiments to verify simulation models.

- Physical Rock Structure: Mimics actual rock structures, providing a more realistic environment for testing EOR methods.

- Random, Uniform or Physical Rock Structure with a vertical crack: Help to provide insight how such a crack or void will influence oil recovery. The crack product is available with a 150, 400 or 600µm wide crack. The crack has a length of 8mm.

- 1000 mD Physical Rock Structure: Mimics a different actual rock structures, fabricated in Silicium instead of glass to create narrower channels. Resulting in a lower Darcy number. Due to the Silicium, the chip is not transparent, but has more contrast between channel and walls when transitioning between gas and liquid.

- Hydrophobically coated chips: Are available of all the products above.

The promising solution of EOR chips

As the resource subtraction industry faces increasing pressure to improve efficiency and reduce environmental impact, EOR chips represent an effective solution. By providing insights into subsurface processes, these microfluidic chips help improve the future of energy extraction. With Micronit's expertise and range of EOR chip options, oil and gas companies can stay at the top of the game with this technological advantage. Micronit is a leader in the development and manufacturing of EOR chips, supporting a diverse range of clients from innovative start-ups to global industry leaders. By collaborating with Micronit, customers can leverage the company's extensive experience and high-quality microfluidic solutions to advance their oil recovery projects.

References:

- Lifton, V.A. (2019). Microfluidics: an enabling screening technology for enhanced oil recovery (EOR). Lab on a Chip, 16(10), 1777-1796. https://doi.org/10.1007/s13202-019-0610-4

- Mohammadi, S., & Maghzi, A. (2019). Investigation of Fluid Behavior in Porous Media Using Microfluidics: A Review. Journal of Petroleum Science and Engineering, 176, 1146-1169. https://link.springer.com/article/10.1007/s13202-019-0610-4

- Conn, C.A., Ma, K., Hirasaki, G.J., & Biswal, S.L. (2014). Visualizing oil displacement with foam in a microfluidic device with permeability contrast. Lab on a Chip, 14(20), 3968-3977. https://www.scirp.org/html/5-2890090_90279.htm

- Géraud, B., Allais, C., Grenier, A., Boussour, S., & Fabbri, A. (2021). Simply built microfluidics for fast screening of CO2 foam surfactants and foam model parameters estimation. Journal of Petroleum Science and Engineering, 200, 108418. https://doi.org/10.1016/j.apenergy.2021.116815