shopping_basket

Enhanced Oil Recovery (EOR) Chip - Uniform network - Hydrophobic Coated

SKU

11002198

Availability:

check_circle In stock

$904.85

per pack of 3

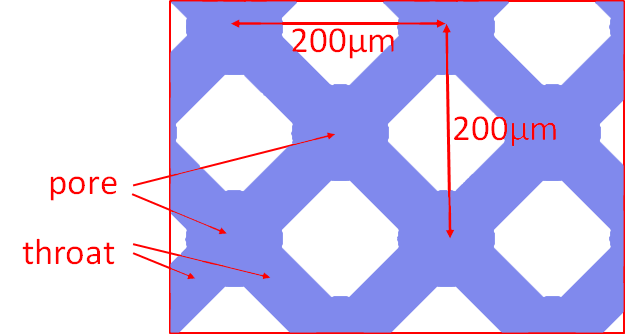

Pack of 3 coated Enhanced oil recovery (EOR) chips with a uniform rock network structure.

The uniform network structure has the following properties:

| Dimensions throat | |

| Channel width | 50µm |

| Channel depth | 20µm |

| Dimensions pore | |

| Pore diameter | 90µm |

| Pore depth | 20µm |

| Unit of measurement | pack of 3 |

|---|---|

| Alternative item references | 02198, EOR.UN.20.2 |

| Application | Enhanced Oil Recovery |

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| EOR network type | Uniform |

| Coating | Hydrophobic coating |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| EOR.UN.20.2 - Drawing | Drawing for the EOR porous medium chip with Uniform Pore Network. Items 02978 and 02198 | 378.2 KB | Download |

Customer Questions

We found other products you might like!

- Enhanced oil recovery (EOR) setup - low pressure (no pumps included)

From $2,081.50

To $10,256.87

- Enhanced oil recovery (EOR) setup - high pressure (no pumps included)

From $2,398.60

To $10,168.54

- Basic microfluidic setup - topconnect (no pumps included)

From $2,081.50

To $25,420.81

- EOR starter kit low pressure - topconnect (incl. syringe pumps)

From $4,755.30

To $8,499.27