shopping_basket

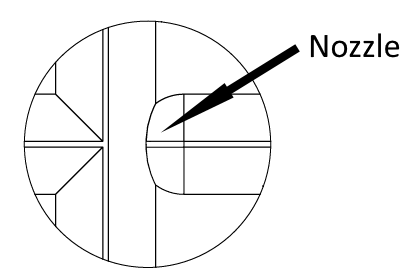

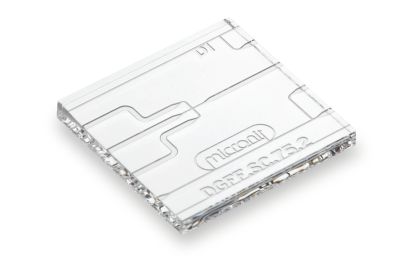

Focused flow droplet generator - nozzle 50µm - coated - topconnect

SKU

11006011

Availability:

check_circle In stock

$787.92

per pack of 3

Pack of 3 hydrophobic coated focused flow droplet generator chips with a nozzle size of 50µm. For use in combination with our topconnect interfacing.

Recommended reference droplet size range: 40-90µm

For creating water-in-oil droplets.

The reference droplet size range is based on a reference experiment with Silicone oil 5cSt and DI water combined with 2% v/v Tween 20 or Tween 80.

Pack of 3 hydrophobic coated focused flow droplet generators. The channels have an oval shape and the design fetaures a nozzle with a height of 50µm and a width of 72µm which is located in the exit channel at the junction.

Around the junction, the channels have a height of 83µm and a width of 88µm. The inlet/outlet channels have a height of 83µm and a width of 433µm.

This design doesn't includes on-chip filters. It's recommended to use external .

| Unit of measurement | pack of 3 |

|---|---|

| Coating | Hydrophobic coating |

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| Fluids | Water droplets inside an oil flow (coated, hydrophobic surface) |

| Nozzle size | 50µm |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| DGFF.50 - Drawing | Drawing for 50µm Topconnect Focused Flow Droplet Generator. Items 01366 and 00877. | 179.6 KB | Download | |

| Droplet Generator Guide | 617 KB | Download | ||

| DGFF.10 - Drawing | Drawing for 10µm Topconnect Focused Flow Droplet Generator. Items 01341 and 00935. | 159.2 KB | Download | |

| DGFF.75 - Drawing | Drawing for 75µm Topconnect Focused Flow Droplet Generator. Items 00970 and 00580. | 193.6 KB | Download | |

| Surface wetting properties | 220.3 KB | Download | ||

| Flow rate instructions | 303.6 KB | Download | ||

| How to prevent clogging | 153 KB | Download | ||

| Using the right surfactants | 168.8 KB | Download |

Customer Questions

We found other products you might like!

- Droplet generation setup - topconnect (no pumps included)

From $2,132.84

To $12,779.65

- Product bundle with interfacing and microfluidic chips

From $2,132.84

To $26,951.83