shopping_basket

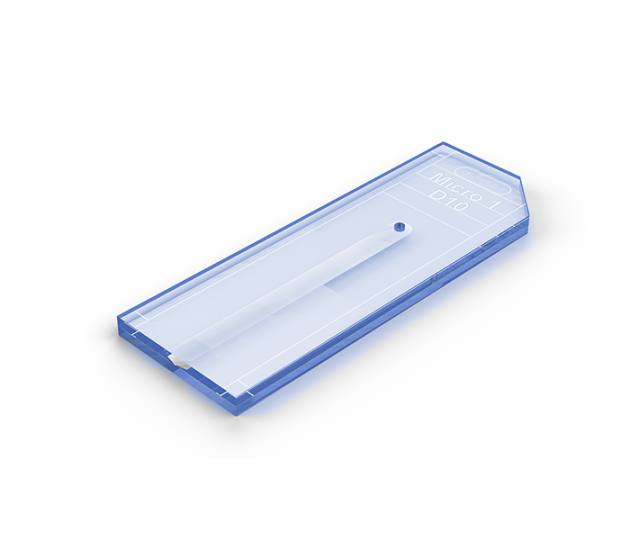

Liquid MicroSheet Nozzle - Micro 1

SKU

11003385

Availability:

Available within 4 weeks.

$3,538.39

per pack of 10

Pack of 10 liquid nozzles chips to create a micro-liquid sheet, using a single fluid.

The Micro 1 sheet thickness is in range 1µm to 0.3µm.

Application

These nozzles create free liquid sheets that are excellent targets for surface studies or bulk studies with soft X-rays. The sheets are flat and smooth, making them ideal targets for optical laser pumps or probes. The thickness of the sheet is on a microscale and varies along the sheet with distance from the nozzle. It is largely independent of flow rates, providing stable targets despite pump fluctuations.

Nozzle type

Micro 1 - Makes the smallest sheets from arround 1 µm to 0.3 µm in thickness

| SKU | Name | Q (Typical flow rate) | Sheet Length at Q | Sheet Width at Q |

| 11003385 | Micro 1 | 2 ml/min | 2.5 mm | 0.40 mm |

Alternatives

Interfacing

Sheet and converging nozzles both use the same interfacing concept, which is not compatible with other products in the store. Micronit can connect you with a third party that can supply a compatible interfacing tool.

Publications

| Year | Titel | Author | Link |

| 2022 | Sub-micron Thick Liquid Sheets Produced by Isotropically Etched Glass Nozzles | Christopher J. Crissman et al | https://doi.org/10.1039/D1LC00757B |

| 2022 | Microfluidic liquid sheets as large-area targets for high repetition XFELs | David J. Hoffman er al | https:/doi.org/10.3389/fmolb.2022.1048932 |

| 2020 | Liquid-phase mega-electron-volt ultrafast electron diffraction | J P F Nunes et al | https://doi.org/10.1063/1.5144518 |

| 2018 | Device design and flow scaling for liquid sheet jets | Byunghang Ha et al | https://doi.org/10.1103/PhysRevFluids.3.114202 |

| Unit of measurement | pack of 10 |

|---|---|

| Interface type | Topconnect - product specific |

| Details for interfacing | This product require an interfacing tool supplied by a third party, see Product Questions for details. |

| Chip material | Borosilicate glass |

| Coating | No coating (hydrophilic) |

| Nozzle Width | 45µm |

| Jet Angle | 30 degrees |

| Nozzle type | Micro 1 |

| On chip filter | No |

| Fluids in Sheet | Single Fluid |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| 11003385 - Drawing | Technical drawing for Converging Sheet Nozzle Micro 1 | 96.3 KB | Download | |

| Converging nozzles - How to use | This guide will explain how a setup using the converging nozzles can look like and how a liquid sheet can be created. | 1022 KB | Download | |

| Spec sheet - Liquid MicroSheet nozzles - Micro 1 | Specification details for the Micro 1 Liquid MicroSheet nozzles. | 198.7 KB | Download |

Customer Questions