shopping_basket

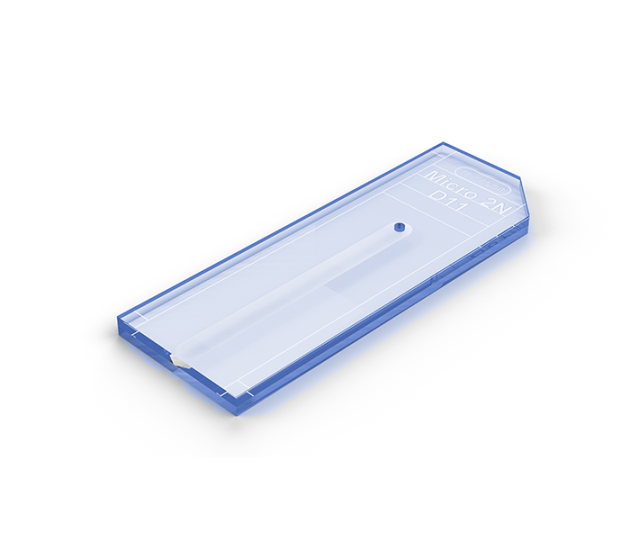

Liquid MicroSheet Nozzle - Micro 2N

SKU

11003383

Availability:

check_circle In stock

$2,416.77

per pack of 10

Pack of 10 liquid nozzles chips to create a micro-liquid sheet, using a single fluid. The sheet thickness is in range 2µm to 0.6µm and the width at the reference point is 0.32mm.

Application

These nozzles create free liquid sheets that are excellent targets for surface studies or bulk studies with soft X-rays. The sheets are flat and smooth, making them ideal targets for optical laser pumps or probes. The thickness of the sheet is on a microscale and varies along the sheet with distance from the nozzle. It is largely independent of flow rates, providing stable targets despite pump fluctuations.

Nozzle type

Micro 2N - is a narrow version of which can be used when a smaller sheet width is needed. The more narrow aspect ratio is also useful for running high concentration samples in vacuum to reduce spray from sheet rims. Sheets are in range 2 µm to 0.6 µm in thickness.

Available products

There are currently three nozzle types available for different sheet thickness needs.

| SKU | Name | Q (Typical flow rate) | Sheet Length at Q | Sheet Width at Q |

| 11003383 | Micro 2N | 3.0 ml/min | 2.2 mm | 0.32 mm |

Alternatives

Interfacing

Sheet and converging nozzles both use the same interfacing concept, which is not compatible with other products in the store. Micronit can connect you with a third party that can supply a compatible interfacing tool.

Publications

| Year | Titel | Author | Link |

| 2022 | Sub-micron Thick Liquid Sheets Produced by Isotropically Etched Glass Nozzles | Christopher J. Crissman et al | https://doi.org/10.1039/D1LC00757B |

| 2022 | Microfluidic liquid sheets as large-area targets for high repetition XFELs | David J. Hoffman er al | https:/doi.org/10.3389/fmolb.2022.1048932 |

| 2020 | Liquid-phase mega-electron-volt ultrafast electron diffraction | J P F Nunes et al | https://doi.org/10.1063/1.5144518 |

| 2018 | Device design and flow scaling for liquid sheet jets | Byunghang Ha et al | https://doi.org/10.1103/PhysRevFluids.3.114202 |

| Unit of measurement | pack of 10 |

|---|---|

| Interface type | Topconnect - product specific |

| Details for interfacing | This product require an interfacing tool supplied by a third party, see Product Questions for details. |

| Chip material | Borosilicate glass - D263 |

| Coating | No coating (hydrophilic) |

| Nozzle Width | 100µm |

| Jet Angle | 50 degrees |

| Nozzle type | Micro 2N |

| On chip filter | No |

| Fluids in Sheet | Single Fluid |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| 11003383 - Drawing | Technical drawing for converging sheet nozzle Micro 2N | 95.8 KB | Download | |

| Converging nozzles - How to use | This guide will explain how a setup using the converging nozzles can look like and how a liquid sheet can be created. | 1022 KB | Download | |

| Spec sheet - Liquid MicroSheet nozzles - Micro 2 | Specification details for the Micro 2/ Micro 2N Liquid MicroSheet nozzles. | 173.8 KB | Download |

Customer Questions