shopping_basket

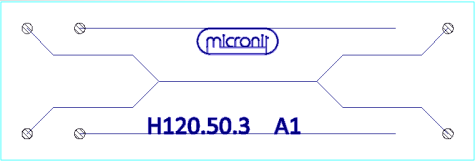

H-shaped channel for boundary flow experiment - 120 x 50µm - Thin bottom

SKU

11003578

Availability:

check_circle In stock

$470.21

per pack of 3

H-shaped flow channel, ideal for boundary flow experiments. The channels have a width of 120µm and height of 50µm. A thin bottom layer (#1.5 coverslip) is used to support high resolution imaging. Use of D263-Bio minimizes autofluorescence for most colors of fluorescent dies.

This H-shaped flow channel is an ideal solution for boundary flow experiments in which two liquids will flow in parallel and only diffusion will occur at the interface of both flows.

The channels are etched into borosilicate glass (D263-Bio which creates extremely smooth channels which are fully transparent. The glass thickness of the bottom layer is comparable to a #1.5 coverslip. D263-Bio glass offers lowest autofluorescence for most colors of fluorescent markers. Those aspects allows high resolution imaging.

The channels have a width of 120µm and height of 50µm.

The main channel has a length of 14.8mm, the inlet/outlet structures a length of 14.5mm

The channel profile is as follow:

The chip has a thickness of 1.3mm, the height above the channel is 1050µm.

The height below the channel is 175µm.

| Unit of measurement | pack of 3 |

|---|---|

| Interface type | Topconnect |

| Chip material | Borosilicate glass - D263 bio |

| Chip thickness | 1.3mm |

| Number of inlets | 2 |

| Number of outlets | 2 |

| Channel Width | 120µm |

| Bottom thickness | 175µm bottom layer |

| Coating | No coating (hydrophilic) |

Customer Questions

We found other products you might like!

- Basic microfluidic setup - topconnect (no pumps included)

From $2,166.01

To $26,452.87

- Observation starter kit - topconnect (incl. syringe pumps)

From $4,441.62

To $5,359.64