shopping_basket

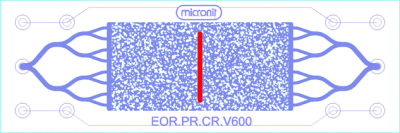

Enhanced Oil Recovery (EOR) chip - Physical Rock network

SKU

EOR-Physical Rock

Availability:

check_circle In stock

As low as $859.41

per pack of 3

Pack of 3 uncoated Enhanced oil recovery (EOR) chips with a physical rock network structure.

Our Enhanced Oil Recovery chips simulate porous media and are frequently used for research on the effects of gas injections in oil fields, emulsification chemical development, microbiological enhanced oil production, and modeling and development of computer simulation models.

The chips are available in three designs as listed below and can be supplied with or without a hydrophobic coating. By default glass behaves hydrophilic. The optional coating is applied on a best effort basis, so some areas where geometries are not interconnected may remain uncoated.

The channel design of the physical rock structure is based on an (edited) scan of a real rock. This explains the irregularly shaped grains.

| Unit of measurement | pack of 3 |

|---|---|

| Alternative item references | 02976, EOR.PR.20.2 |

| Application | Enhanced Oil Recovery |

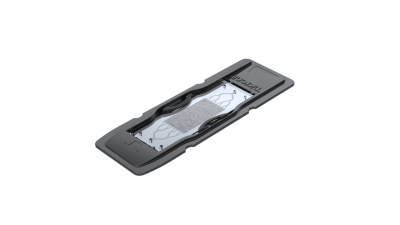

| Interface type | Topconnect |

| Chip material | Borosilicate glass |

| EOR network type | Physical Rock |

| Permeability (Darcy) | 6.62-7.79 |

| Icon | Label | Description | Type | Size | Download |

|---|---|---|---|---|---|

| EOR.PR.20.2 - Drawing | Drawing for the EOR porous medium chip with a Physical Rock Network. Items 02976 and 01954 | 139.5 KB | Download | |

| Permeability determination of catalogue chips | This documents describes how permeability values of EOR chips with a Uniform Network, Random Network and Physical Rock network are determent. | 983.2 KB | Download |

Customer Questions