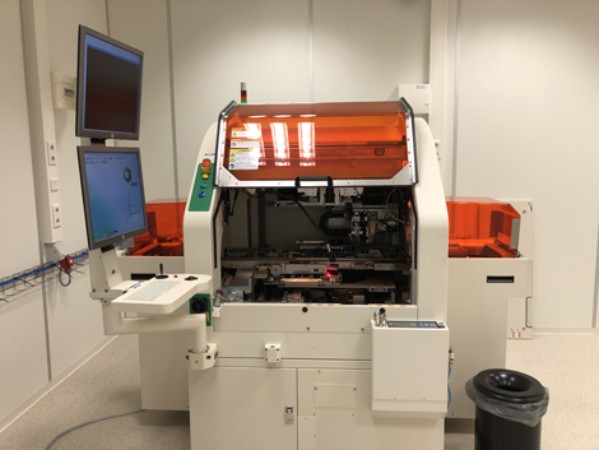

What can this machine do?

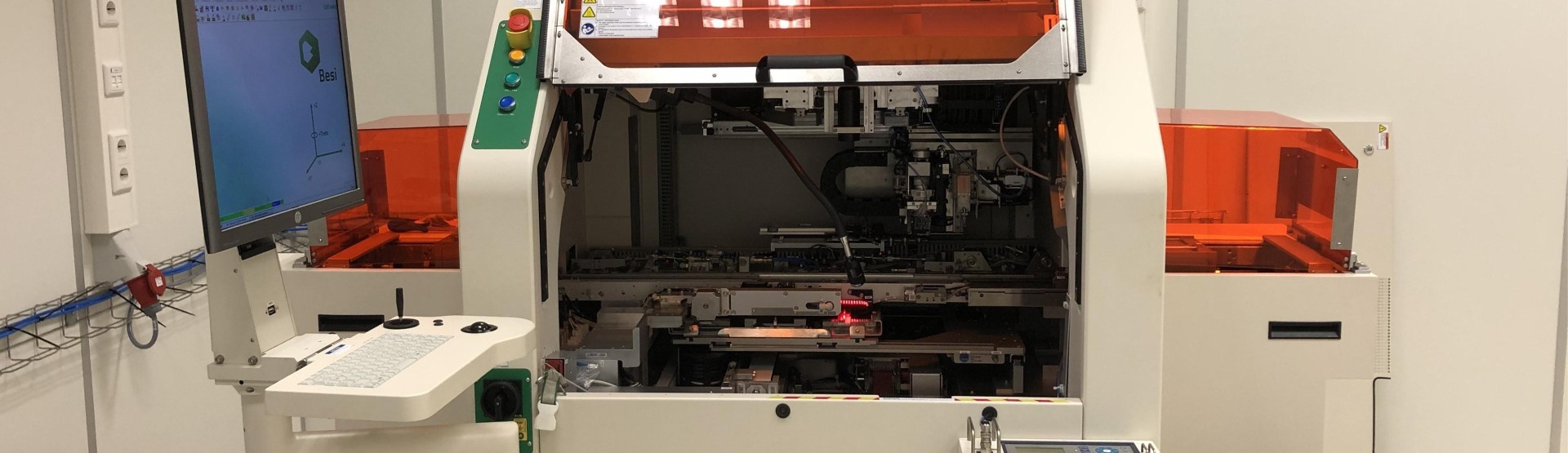

The pick and place machine performs multiple operations such as chip picking and placing, dispensing, assembly, packaging, and flip-chipping. These tasks are performed with high position accuracy and reproducibility. The substrate and die can be loaded in the machine as a wafer or in a carrier and can be recognized and bonded together with the help of a vision recognition system and pick and place tools.

Multitude of functionalities

This machine can perform many different process steps, allowing for maximum flexibility depending on the type of application.

Let’s take a closer look at its separate functionalities.

Dispensing

The machine is fitted with two types of dispensers. For precise dispensing of, for example, adhesives, this machine has a pressure-time dispenser, with an optional temperature control. The machine is also equipped with an Auger valve dispenser for dispensing more viscous substances, with very high volume accuracy. For precision-dispensing of small volumes in nano and picoliter range, the machine can be further upgraded with a jetting valve.

Assembly

Assembly relies on the machine bringing the two components into contact using a pickup tool and applying a specific bonding force. The bond force as well as placement location can be specified precisely, resulting in highly reproducible assemblies with alignment accuracy down to 20-50 micron, depending on the application. Apart from this, the adhesive can be cured with UV light that can be applied in specified doses by the UV-curing bond head that is integrated in the machine or via LEDs loaded in a fixture below the bonding location. This allows for bonding flexibility depending on the type of materials used in the assembly.

Visual inspection

The vision recognition system makes use of three different high-resolution cameras, which can be used for substrate and die recognition and alignment marks search. Using the built-in software, the user can program different levels of position accuracy search based on one, two or more points, depending on the alignment accuracy needed. To achieve best results, the individual substrates and dies should include alignment marks, but patterns can also be programmed.

The machine can also perform post-bond inspection: after the dispensing step, the camera registers where the glue is and if it has covered the whole of the required surface (for certain types of glues only) or after the bonding step, to inspect the resulting alignment accuracy.

Flip chip

This is a process step that flips the chips 180 degrees (upside down, so to speak). This feature is very useful for chips that have been functionalized with a biological substance or contain sensitive structures. Usually these chips arrive with the active side up to prevent damage when putting them in a container. To bond these chips with a substrate, a flipping step is necessary, after which the regular pick and place tool can pick up the chip and complete the bonding process.

Why are we excited about this machine?

- Speed - High-volume production of 1.250 units per hour (depending on the type of application).

- Accuracy - Assembly precision of between 20-50 microns.

- Versatility - All or a selection of these functionalities can be executed automatically by this machine.

The pick and place machine also offers the possibility to be placed in line with other machines, in order to achieve a highly specialized, fully automated production line.

This machine will be qualified according to the new GMP regulations. With tools like these, we at Micronit are able to produce complex lab-on-chips for our customers with more speed and accuracy.

Do you think this machine can be of use in the manufacturing process of your (future) product? Would you like to discuss this with one of our specialists? Contact us straight away!